Some time in 2004, I bought my first DSLR. It was the Nikon D70. I still have it. A few years back, I had it converted to infrared, and I still use it today.

Now, I have the yen to use a straight monochrome DSLR. Problem is, they are too rich for me! So, I thought maybe I could convert a D70 to monochrome. I guess it can be done, here is some information: Debayering Nikon D70 sensor

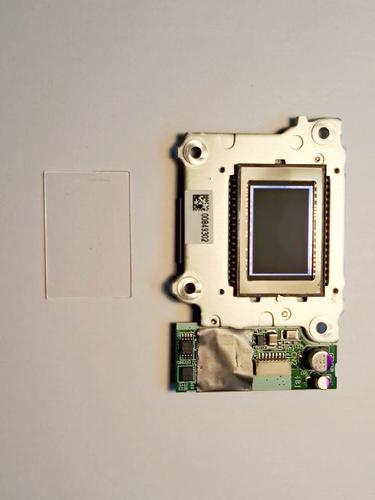

Since I don't want to destroy my working D70, I have purchased one from the big trading site for $35.00 plus shipping. I got it today, and it really works! Here are a few quick images made with it.

I have instructions for the disassembly of the D70 here: Nikon D70

I'm not sure when I can get to this, or if I will be successful, but I think if I can find the time, it should be fun!